Biorefining: The Low-risk Opportunities to Produce Furfural

We have previously reported on:

The Masterkey to the furfural business and

Why the production of furfural is not Rocket Science.

In the presentation below, we showcase the last 12 projects with links to the summaries of our consulting activities (business plans, feasibility studies, concept plans, project development plans, etc.)

Related Sites

Connecting-The-Dots™ (Creating Biobased Businesses: About our experience to connect the many "dots" of the value chains that every successful biobased business needs)

µ-BioRefinery™ (in propinquitatem ad biomasa; Bringing biorefining in proximity to biomass)

GreenEnergyPark™ (Smart biomass - agricultural/forest residues - conversions to energy, chemicals and commercial products)

International Furan Technology (An independent developer and implementer of furfural process technologies)

Connecting-The-Dots™

For the agri (biomass) processing, sugar, pulp&paper, etc. industries, we provide knowhow and technology to convert (residual) biomass to chemicals and energy.

For owners of biomass we offer technology and market access, creating investment opportunities in the cleantech space.

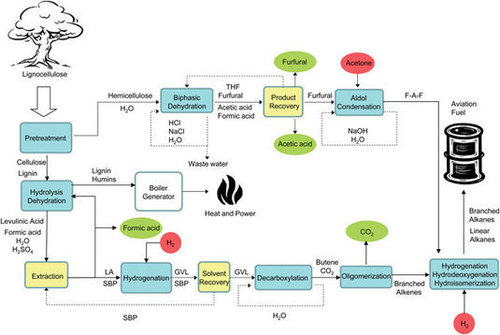

The essential technical challenge facing us, and the world in general, is the complete beneficiation of cellulosic material. We strive to provide viable and practical solution. Contact us to discuss the economic potential of your biomass.- Biorefineries

- Furfural...